We are ambitious and ready for challenges! Hire Us

// Perspectiva Solutions - Manufacturer of cable harnesses for the militaryLooking for reliable wire harnesses

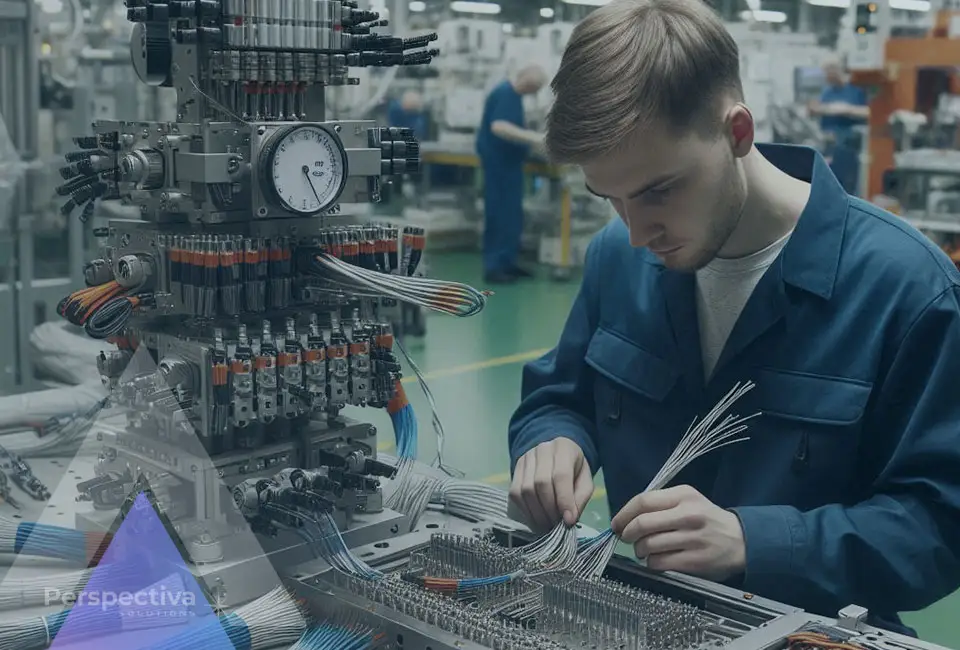

Looking for reliable wire harnesses

for the defense industry?

At Perspectiva Solutions, we specialize in manufacturing the highest quality wire harnesses for the defense industry that meet stringent military standards. With years of experience and a proven history of manufacturing wire harnesses for military vehicles. You can trust us to deliver the highest quality products to meet your specific needs and requirements of the defense sector.

Are you involved in the production of military equipment?

// Wiring harnesses for military vehicles

Our cable harnesses meet military standards, guaranteeing quality, performance and reliability

Branded components

Branded connectors and high-quality cables for special tasks.

Quick implementation

We understand the urgency of your projects, so we offer fast turnaround time without compromising quality.

Customized solutions

We can customize our products to customers' exact specifications and requirements.

Team of experts

Our team of skilled professionals is committed to providing the best solutions for the needs of the defense industry.

From design, to prototype, to mass production!

// MIL standards for the defense sector

Working with us is all about the benefits!

High quality and reliability

We focus on the quality of our products. Working with us means that you will receive cable harnesses that meet the highest standards and are reliable in harsh environments.

Adaptation to requirements

We have experience in serving various industries, including the arms industry and the space sector. We can customize cable harnesses to meet the specific requirements of your project.

Technical support

As experts in the production of cable harnesses for the defense industry, we help in selecting appropriate solutions. Our qualified engineers provide technical support at every stage of the project.

Compliance with MIL standards

We operate in accordance with stringent requirements based on MIL standards. Cooperation with us allows you to avoid problems related to non-compliance or lack of certification.

// Perspectiva Solutions - Manufacturer of military cable harnessesProduction of wirie harnesses

Production of wirie harnesses

for the defense industry

The defense industry is one of the key industries for which our company manufactures wiring harnesses. We have extensive experience in designing, prototyping and manufacturing custom wiring harnesses, for the defense industry.

All electrical harnesses are designed by specialists in our engineering department or made based on the design sent by the client. Depending on the order requirement, we also perform cable harness prototyping. We meet customer guidelines in a wide range of component quality, durability, performance and cabling operating environment (e.g. operation of the electrical harness in a vacuum or operation in explosive atmospheres).

Contact us today to learn more about our wire harness manufacturing services for the defense industry.

Our success is our priority!

// Frequent questions about wire harnessesCauses of damage to wiring harnesses

Causes of damage to wiring harnesses

in military vehicles?

Mechanical damage to the electrical harness

Damaged electrical harnesses, such as partial tear or complete breakage of the cable harness. What follows is a lack of proper power supply to electrical consumers required for proper operation. They can often be the main cause of failure of the entire machine or equipment.

Damage to cable insulation

It can cause overheating and damage to the wires. Typical damage, i.e., overheating, can lead to a current breakthrough and ultimately to a short circuit and stop the operation of the device.

There is a high risk of damage to the vehicle, device or machine.

Wiring corrosion

Electrical harnesses operating in harsh environments can be at risk of corrosion, which can lead to machine or equipment failure. To prevent corrosion, electrical harnesses must be regularly maintained and cleaned.

Dirt on the electrical harness

Dirty wiring harnesses can weaken the flow of current and cause interference with machine operation. That's why proper operation of wiring is so important.

Wear and tear on the cable harness

Worn electrical harnesses can be a source of machine or equipment failure. Every electrical harness should be periodically maintained and meticulously checked for safe operation.

Badly matched electrical harnesses

The wrong type and/or wrong thickness of cable can cause problems with the fit of machine or equipment components. That's why it's a good idea to use reputable components and parts and choose a reliable cable harness manufacturer.

Improper wiring harness connection

If the electrical harnesses are connected incorrectly, they can cause problems with the functioning of the entire machine or device.

Misalignment of wiring harnesses

Poorly arranged electrical harnesses can impede access to other components of the machine or equipment, which can lead to problems with their functioning, and ultimately even lead to irreparable damage.

Improper operation and high wear of wiring

One of the most important factors for proper operation is comprehensive wiring maintenance. Cable harnesses, like any other component, also wear out and can be susceptible to mechanical damage, heavy soiling or flooding.

During the operating cycle of a machine or vehicle, wiring may need to be replaced, according to the guidelines given in the cable harness design.

What is the effect of damage to the electric cable

Damage to the electrical cable can cause a short circuit or break the circuit, which can ultimately cause a fire.